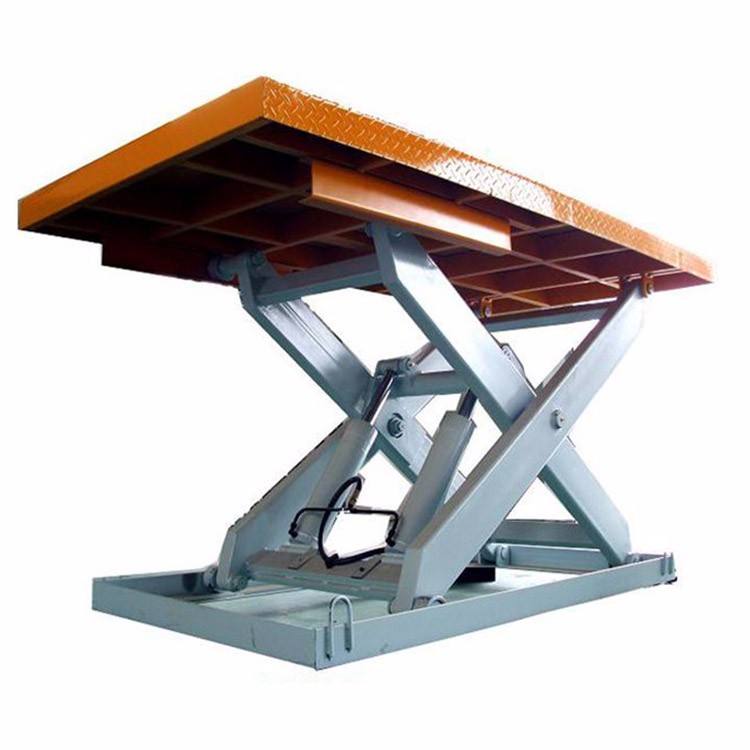

The hydraulic scissor lift, as a mechanical equipment, needs a run-in period at the beginning of use, which is not only a process of man-machine adaptation, but also a process of equipment self-adaptation. So what do you need to pay attention to when using the elevator for the first time?

From the machine itself. When the equipment is first used, the wear rate is the fastest period. The friction surface of the hydraulic scissor lift is rough, the contact area of the mating surface is small, and the pressure on the surface is uneven due to the influence of parts processing, assembly and adjustment. During the operation of the machine, the concave and convex parts of the surface of the parts are embedded with each other for friction, and the metal debris, as abrasive material, continues to participate in the friction, which accelerates the wear of the matching surface of the parts. Therefore, the run-in period easy to cause parts (especially with the surface) wear, wear speed. This time if you do not pay attention to maintenance, but carry out overload work, you will accelerate the early elevator damage.

The fitting gap of newly assembled parts of hydraulic scissor lift is small, and it is difficult to ensure the uniformity of the fitting gap due to assembly and other reasons. Serious friction surface will cause precision fit scratch or bite phenomenon, leading to the occurrence of fault.

The newly processed hydraulic scissor lift is prone to loose parts. In the early stage of use, due to the impact, vibration and other alternating load, as well as the impact of heat, deformation and other factors, coupled with the cause of wear too fast, it is easy to make the original fastening parts loose. So be sure to check the equipment often whether the parts are loose traces.

The hydraulic scissor lift may also leak because of the loose sealing. Under the influence of loose parts, vibration and heat of the machine, leakage may occur on the sealing surface and pipe joints of the machine. Some defects, such as casting and processing, are difficult to be found during assembly and debugging, but due to the vibration and impact effect in the process of operation, such defects are exposed, manifested as oil leakage. Therefore, the run-in period is prone to leakage.

It also takes some time for operators and equipment to get familiar with them. Before use, operators must understand the instructions and precautions, understand the performance and principle of the machine, so as to avoid serious accidents caused by improper operation.

The above are some Suggestions about the hydraulic scissor lift I wish I could help you.