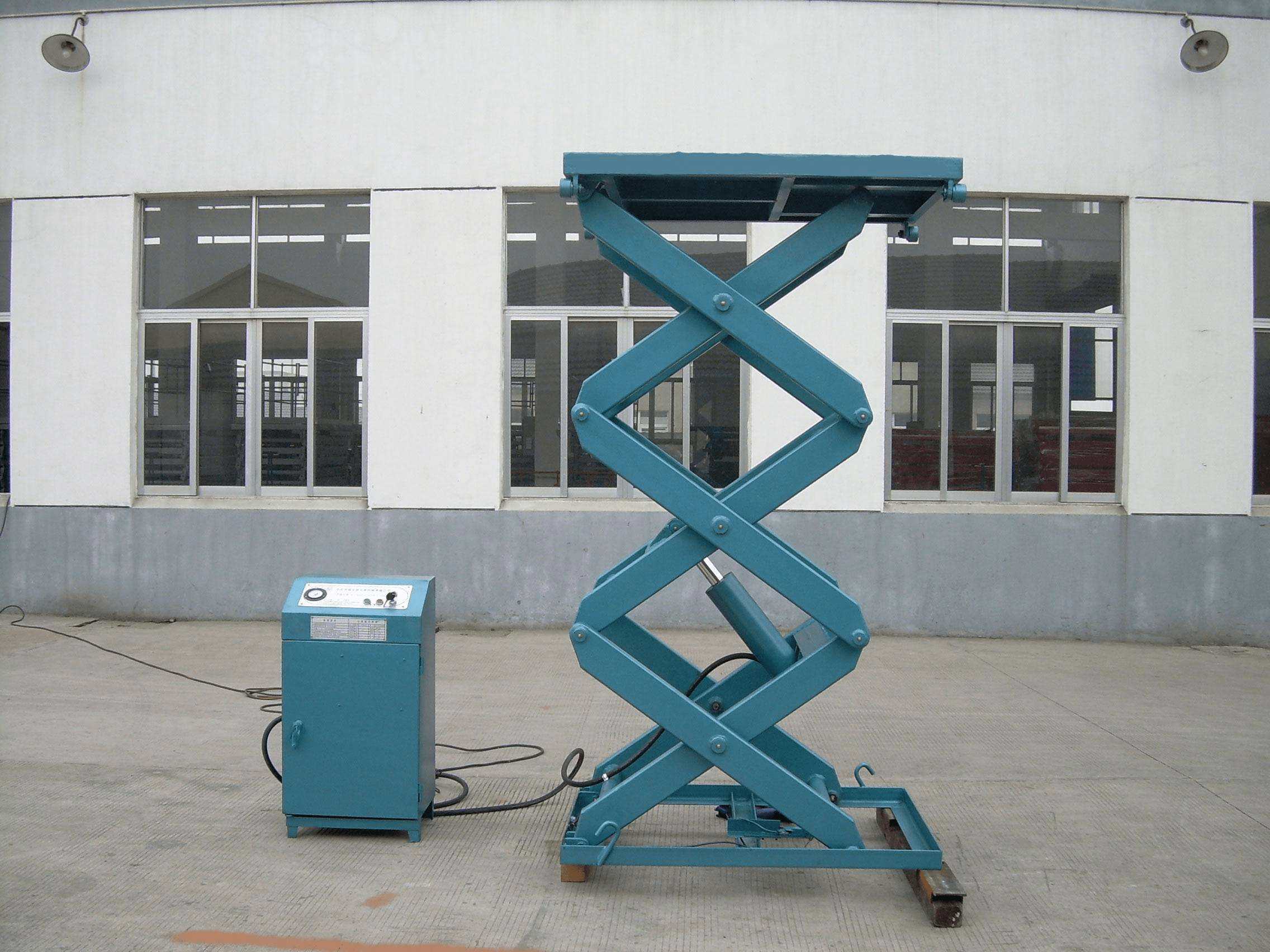

If you use stationary scissor lift for a long time, there will be some wear and tear on it. Let's learn about it together. I hope that was helpful.

Grinding oil regularly between stationary scissor lift pins to reduce wear and noise can prevent accidents. Remove and disassemble the fixed lifting platform drop valve, blow the plunger clean with compressed air, and then load and install it again. Check all hydraulic pipes and joints. Pipes must not be damaged and joints must not be loose. All joints must be tightened.

Oil quality and level of hydraulic oil. The stationary sor lift should be 40 to 50 mm above the bottom of the enclosure. If the hydraulic oil is dark, sticky or has gravel or other foreign matter, it should be replaced in time. Regularly check the wear of the stationary sor lift roller, intermediate shaft and bearing, cylinder pin shaft and bearing, arm hinge shaft and bearing. Between any parts of the hydraulic system, must first unload pressure, so as to avoid the pressure of oil gushing, platform work table suddenly lost oil pressure, table slide.